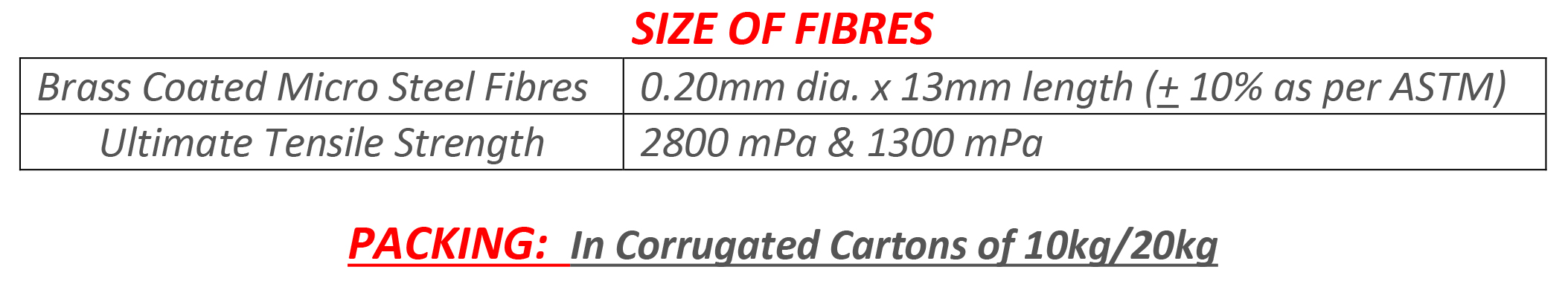

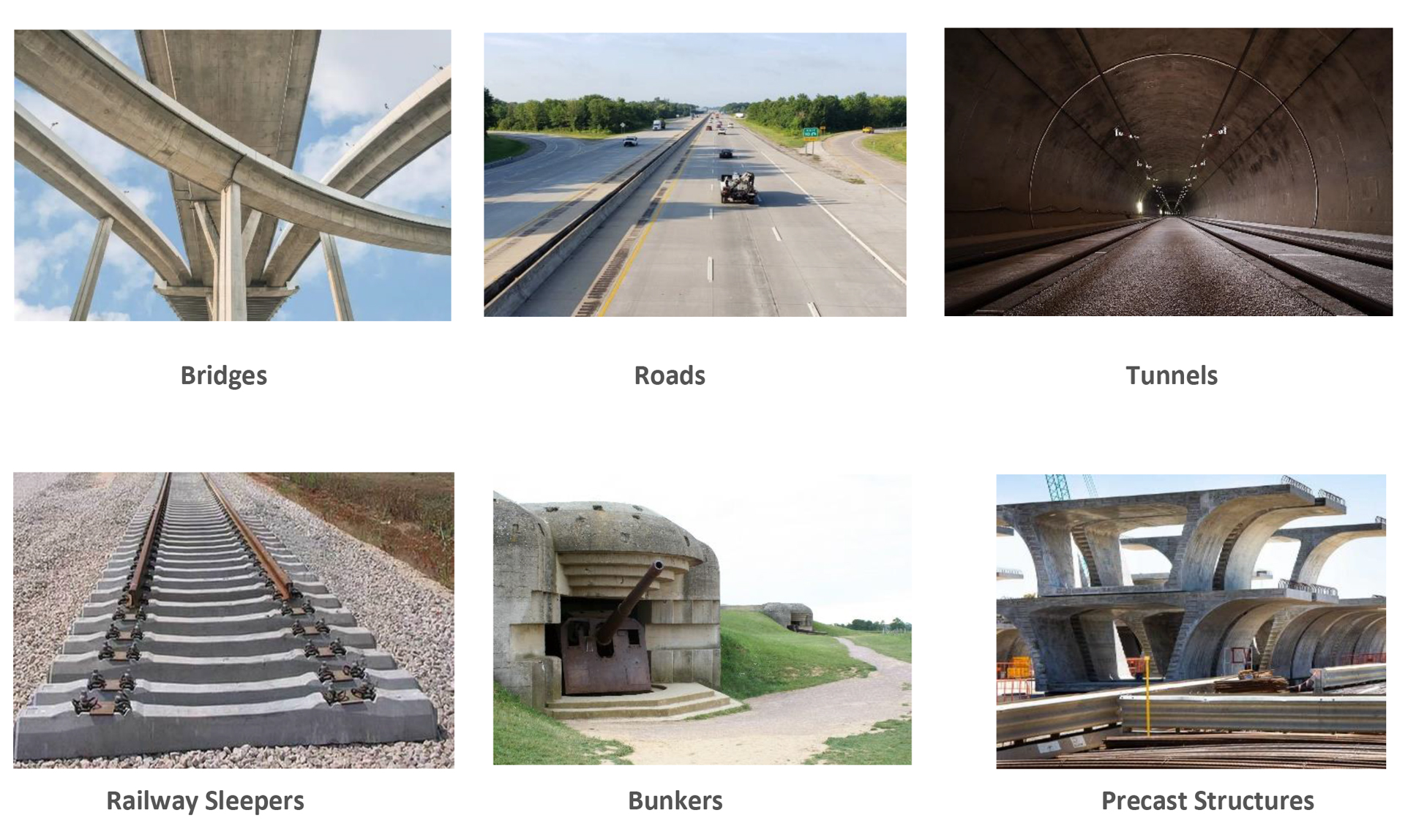

Shaktiman® Brass Coated Micro Steel Fibres (MSMF 2013) is a new and special class of brass coated steel fibres that have been developed in recent years for its exceptional properties of strength and durability. Due to high density of steel fibres in concrete mix, these are ideally used in Ultra High Performance Concrete. These high performing steel fibres can be utilized in structural rehabilitation and accelerated bridge construction, Roads, Tunnels etc., in addition to several other

high performance and special concrete applications.

Strength in UHPC Application

UHPC has a compressive strength 10 times that of traditional concrete. Compressive strength is the ability of a material to resist bending under a load (or in compression). While traditional concrete has a tensile strength of 400 – 700 psi, UHPC has a tensile strength of about 1400 psi.

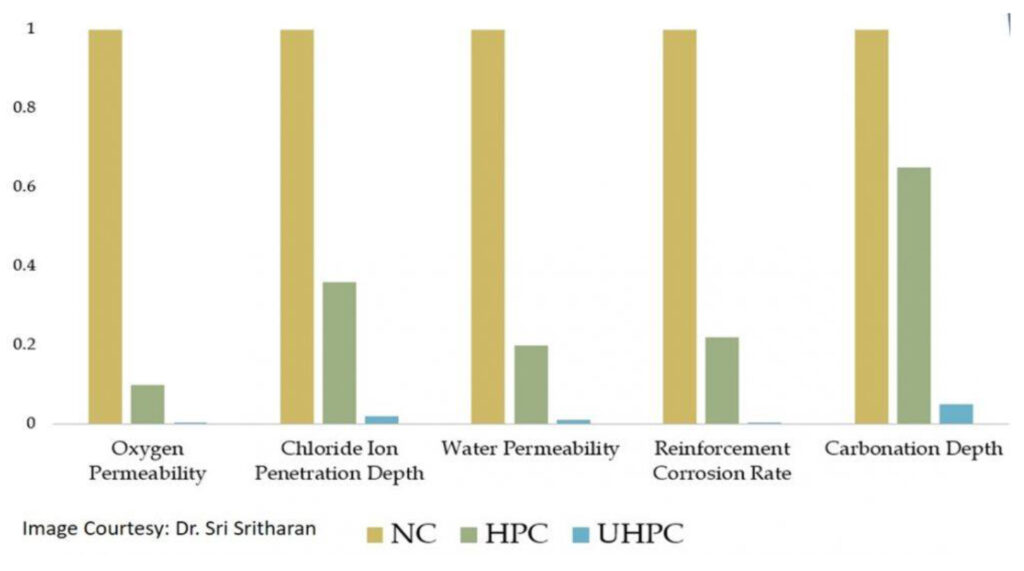

Durability

While the strength Brass Coated Micro Steel Fibres is impressive, it’s durability further exceeds expectations. Durability is measured by how the material performs under extreme conditions. Due to the presence of high density of steel fibres, UHPC has properties similar to hard rock when combined with Brass Coated Micro Steel Fibres Reinforcement.

Abrasion resistance is determined by measuring the amount of concrete abraded off a surface by a rotating cutter in a given time period. Brass Coated Micro Steel Fibres Reinforced Concrete demonstrates excellent abrasion resistance, nearly twice as resistant as normal concrete.

UHPC thus fills a critical gap between structural steel and concrete and opens new areas of applications in the design and construction of structures.

DURABILITY COMPARISON OF UHPC TO NORMAL AND HIGH PERFORMANCE CONCRETE